Short description of PVC

Polyvinyl chloride (PVC) relates to a thermoplastic synthetic material. In appearance is a white powder, without taste and odor, which is insoluble in water, resistant to acids, alkalis, alcohols, mineral oils swells and dissolves in ethers, ketones, chlorinated and aromatic hydrocarbons.

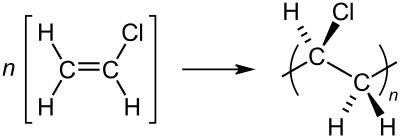

The empirical formula of PVC: [- CH 2 - CHCl -] n

Polyvinyl chloride is applicable in various fields of processing into products such as the production of:

Cable plastic;

Films;

Hard molded products;

Leatherette;

Flooring and carpets;

Wallpaper;

Rubber molded products;

Paints and varnishes;

Containers and packaging;

Products for medicine.

Polyvinyl chloride is plasticized and unplasticized. Various production methods (emulsion or suspension polymerization, bulk polymerization) affect certain properties of the material, which, in turn, vary depending on the following factors:

modification or molecular weight distribution

sopolimeriatsiya and grafting

conversion into the polymer mixture;

re-chlorination and adding:

stabilizers;

additives to further processing;

plasticizers;

dyes and pigments;

antistatic agents;

blowing agents;

excipients.

The most important properties of PVC:

light and weather resistant;

good electrical insulation;

gas-tight;

resistant to rot and decay;

durable;

weatherproof;

It does not rust;

shock-viscous;

It does not need to care for the outer surface;

available in a range of temperatures and heat-resistant formoustoychiv;

hard to ignite and burn without access of fire.

Properties of non-plasticized polyvinyl chloride:

mechanical strength, stiffness and hardness;

normal or high impact strength and resistance to tearing;

durability;

difficult to ignite and is self-flame stops burning;

weather resistance and resistance to chemicals;

good electrical properties at low voltages;

some highly soluble solvents, so well glued together;

well-welded;

It can be used only in a limited temperature range;

It may be transparent or translucent;

preservation of original dimensions due to low shrinkage